Overview

STEM careers

Grade level

Time

Materials

Per Person or Team:

- Stuff to make filters out of: facial tissues, cotton balls, tissue paper, bandage gauze with loose mesh, pipe cleaners, scraps of very thin or loosely woven fabric

- tape, glue

- scissors

- rulers

- Stuff to build the frame for the filter: cardboard, string, craft sticks, paper clips, binder clips

- sketching materials for inventing and improving the design

For the testing box (1 per class)

- shoebox or similarly sized rectangular box

- Stuff to make a curtain for the end of the box: tissue paper, tissue, or paper napkin

- Stuff to hold the student filter upright and in place: cardboard, index cards

- hair blow-dryer(s)

- tape, glue

- Particulate: finely ground black pepper or another spice, whole wheat flour, cocoa powder, and/or similar-sized particles that easily become airborne and can be seen against the filter

- scissors, box cutter

- measuring teaspoon

- Catch-it container: large container for capturing particles that blow out the end of the box

- Optional: index cards, petroleum jelly, or packaging tape for capturing escaped particulate

Steps to prepare a testing box before the activity:

- Cut a hole in one end of the box for the blow-dryer to fit in. The length of the box will be a wind tunnel for the particulate matter to blow through and hit the filter about halfway down.

- Cut off the opposite short end of the box. What the filter didn’t catch will blow out this end of the box and land in the catch-it container. Cover this end with a curtain taped along the top edge. If the curtain doesn’t fly up by at least 45 degrees when the blow dryer is on, the airflow is too blocked, and the filter needs to be redesigned.

- Attach strips of cardboard or similarly stiff material midway inside the box to make bracing that will keep the students’ filters upright and in place.

- Lastly, cut a small flexible slot into the top of the box between the blow-dryer and the filter bracing. This is where you will pour the particulate matter during each test.

Introduce

Particulate matter, or PM, is a term for the tiny bits and pieces of stuff that float in the air. Some are big enough to see, like dust, soot, and pollen. The hairs and mucus in our noses act as natural filters to keep much of this matter from getting into our lungs, while our eyelashes help keep it out of our eyes. But we can’t filter all the PM out of the air, especially if we live where there is a lot of air pollution or if there’s a wildfire. Air filters help to protect our health in these situations.

Challenge

- Design an air filter that catches visible particles as they are blown through the filter.

Success Criteria

- The air filter captures more than 50% of the particles when air blows through it (compare the filter to the amount of particulate that escapes).

- The filter is sturdy enough to withstand air blowing on it and doesn’t fall over.

- The filter is replicable.

Constraints

- Use only the materials provided (but you don’t have to use them all).

- The filter must fit snugly in the testing box.

- The filter must allow enough airflow to raise the curtain at the end of the box by at least a 45-degree angle.

- The filter has to capture an observable amount of particulate matter.

Instructions

- Share the challenge, success criteria, and constraints with students. Go over the size requirements for the air filter. Optional: To give students an idea of how similar filters are designed for practical use, show them an air filter from your gas furnace, vacuum cleaner, air purifier, or other appliance.

- Show students the materials. Get students thinking with some preliminary questions:

- Which of the materials allow air to flow through them? How do you know?

- What qualities will the filter need in order to catch the particles?

- What will make the filter sturdy enough to withstand the blast of air from the blow-dryer?

- Show students how their filters will be tested using the testing box that is already set up. Point out that the frames for the filters need to fit inside the ledges you attached inside the box to hold the filters steady.

- Distribute the materials. Give students time to explore the properties of the materials and do some experimenting as they plan their design. Ask them to think about whether the filter would work better if it had multiple layers or if it was very thin instead. How can they design their frame to help the filtering materials stay steady?

- Ask them to think about their experiences wearing different types of face masks. Do cotton masks or masks with multiple layers/filters feel different from medical masks? Is there a point where there are too many layers? Encourage them to test ideas and determine if their filter blocks too much airflow with the blow-dryer before they finalize their design.

- Remind them that the end of the blow-dryer will get very hot, so be careful not to touch it and turn the blow-dryer off whenever it isn’t in use for testing.

- Tell students to build their air filters. Assure them that after they test their first designs, they can make changes and improvements. Have students do an airflow test of their air filters to make sure the end curtain raises by at least 45 degrees.

Air filter testing box with container ready to contain wayward particles.

- Measure a consistent amount of particulate (ground pepper or similar) onto the top of the box for testing (1–2 teaspoons should work depending on the size of your testing box). While the blow-dryer is running, pour the particulate into the slot between the blow-dryer and the filter. Students should compare how much particulate their filter caught and how much landed in the catch-it container. (Optional: For the comparison, you can pour the contents of the catch-it container onto an index card with petroleum jelly or packaging tape sticky side up. This would help students better visualize if their filter caught more than 50% of the particulate.) The filter with the least amount of particulate in the catch-it container is the one that worked best.

- Once everyone has had a chance to test their design, hold a discussion. What were the characteristics of the air filter that captured the most particulate?

- Tell students to gather another set of materials and try again. For teams whose filters were really effective, see if they can create a filter that captures a finer particulate such as cocoa powder.

BRAINSTORM SOLUTIONS

BUILD AND TEST

EVALUATE AND REDESIGN

Guiding questions

- Where is the particulate going—all around the shoebox, straight out into the catch-it container, or is some of it getting caught in the filter?

- What happens if you face your filter material the other way? Does it do a better or worse filtering job?

- What is the weak point of the filter? How much air is blocked by the filter?

- What happens if you change the angle of the airflow? Will more particulate be captured?

Engineering & science connections

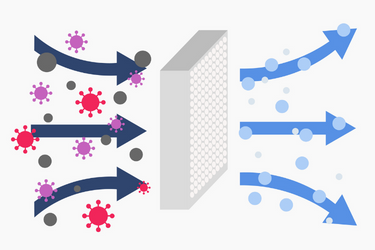

- One form of pollution indoors is airborne particulate, known as particle pollution. All kinds of substances can suspend in the air, sometimes just for a moment: lint, fiber, dead skin cells, pollen, and human-caused pollution. Air filters remove these substances with filtration material. This material captures these particles when air is forced to flow through it. The particles are caught because the openings in the material are even smaller than the particle.

- Engineers design air filters for many different purposes. In heating, ventilation, and air conditioning systems, air filters protect equipment from accumulating dirt and capture contaminants in the air. Engineers also design them for aircraft, car engines, satellites, and space shuttles. Factories use them to filter and clean exhaust before releasing it into the atmosphere.

- How do scientists and engineers measure the effectiveness of air filters? They use MERV ratings: Minimum Efficiency Reporting Value. The higher the number, the better the filter is at removing small contaminants. For COVID, you want a MERV 13 or higher. The highest possible rating is 16.

- All over the country, schools are making their own air filters to keep kids safe from COVID. The design comes from Richard Corsi, the dean of engineering at UC Davis. To make one, you need a box fan, cardboard, duct tape, and four air filters of MERV 13. These simple filters last the whole year and take about half an hour to assemble. They can clean 600 cubic feet of air a minute, which is better than many portable air cleaners that are more expensive. www.cleanaircrew.org/box-fan-filters

0 Comments