Overview

Materials

Per Student or Team:

|

Per Class:

|

Instructions

Students get a taste of what professional engineers face as they work under deadline and within budget and design constraints to construct a structure that adheres to specific performance requirements.

Students get a taste of what professional engineers face as they work under deadline and within budget and design constraints to construct a structure that adheres to specific performance requirements.

- Decide whether students will work individually, in teams, or in small groups, and gather materials accordingly.

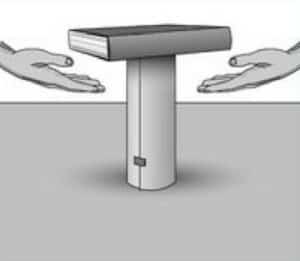

- Tell students the performance requirements for their design: A paper structure that will support a standard hardcover textbook at least 12 inches above a flat surface for at least 30 seconds.

-

Explain the rules and design constraints:

Explain the rules and design constraints:

- The structure must be made entirely of paper and masking tape.

- Paper used for construction must be standard size printer or notebook paper (8.5″ x 11″).

- Each sheet of paper used during construction will cost $1,000, and every quarter inch of tape taken from the 10″ strip will cost $100. This includes all materials used or damaged in construction, even discarded materials.

- Design and construction must be completed in 30 minutes.

- A structure cannot be load-tested before it is declared complete.

Students may weigh and measure the load (the book) at any time during construction.

Students may weigh and measure the load (the book) at any time during construction.- The winning design is the one that holds the book for at least the minimum time and spends the least on materials.

- Explain the process: Students should brainstorm designs and then construct their structure. When their structure is complete, it will be load-tested with the textbook.

- Pass out materials to the students and then start the timer.

- When students complete their structures, load-test them as follows:

- Place structure on sturdy level surface.

- Gently place textbook on paper structure.

- Start timer (book must be supported for 30 seconds).

- Measure to make sure that the book is at least 12 inches above the flat surface.

Guiding questions

-

What do you need to know about the load that your structure will have to support?

-

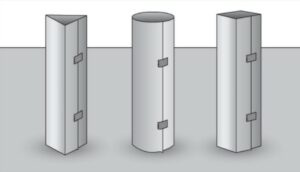

What shapes help make paper strong enough to hold weight?

-

Considering that each piece of paper costs $1,000, how can your design use as few pieces of paper as possible, while still meeting the requirements?

-

Considering that each quarter inch of tape costs $100, how can you conserve tape and still create a strong enough structure?

Engineering & science connections

- Constraints are limitations; for example, if you have only 30 minutes, that’s a time constraint. Other common constraints engineers face include available materials, budget, building codes, and size maximums.

- Building materials come in standard dimensions from the vendor; engineers must adapt their design to make use of these materials. Otherwise, extra money to the budget must be allocated to create customized materials.

- Steel is a good example of a material that can hold a lot of load with very little cross sectional area. When viewed from the end, common steel beams look like an uppercase letter “I”, which is why they are called I-beams. The shape of the steel is what gives it its strength, just like a light piece of paper in the right shape can hold comparatively large loads. Most skyscrapers are made from long and narrow steel pieces built into a frame (columns and beams).

0 Comments