Overview

Materials

Per Team:

- 1 small ball (ping pong or foam golf)

- paper and pencils for designing and planning

A small assortment of each of the following:

- Lever materials

- paint stirrers

- tongue depressor sticks

- plastic spoons

- Fulcrum materials

- thread spools

- dowel sections

- blocks

- toilet paper tubes

- Connective materials

- tape

- rubber bands

- Other building materials

- dixie cups

- cardboard

- popsicle sticks

Instructions

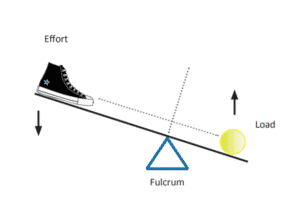

Designing a step launcher explores the use of levers. Levers are quite simple: All you have to do is balance a long and straight beam, like a plank of wood, on an object that lets the plank pivot on the object. The balancing object is called the fulcrum. For a lever to become useful, put an object on one end. That’s the load that will be moved. Put effort on the other—that’s your hand or foot pressing down. When you press down, the load moves. With the right lever, it moves farther or faster than if you just picked it up yourself.

DEFINE THE PROBLEM

- Share the challenge with students: Design a way to launch a small ball off the floor so you can catch it.

- Give students the specs:

- You may only use one foot to make your launcher work.

- The ball must launch upward and high enough for you to catch it.

- Ask students to discuss the characteristics of ping pong or foam golf balls. What makes them so good for hitting horizontally? What could be challenging about getting them to swoosh straight up from the ground, high enough to catch? Make a list of students’ responses.

- Divide the class into teams of 2–4 students and provide each team with a set of materials. Instruct teams to experiment with the materials and plan their design ideas. Note: A lever is not required in the design, but it is likely the most efficient approach.

- Tell students to build their launchers. Assure them that after their first designs have been tested, they can change and improve their launchers.

- During testing, give each team a few tries to show they can launch their ball with one step and have it be caught by the launcher.

- Instruct students to consider what worked and what didn’t, and to combine their own experience with their observations of the other teams’ devices. Tell them to use all this information to tweak their designs and improve them.

- Tell each team to gather another set of materials and try again. Alternatively, for teams whose first design was successful, up the ante: Tell them to design a launcher that sends the ball to a partner standing a certain distance away, that launches into a wastebasket, or that shoots up twice as high.

BRAINSTORM SOLUTIONS

BUILD AND TEST

EVALUATE AND REDESIGN

Guiding questions

- How does the length of a lever affect the trajectory of the ball?

- How does the placement of a fulcrum affect the trajectory of the ball?

- What would students change about their designs if they could use other materials? What materials would they use, and what would they use them for?

- How could the basic design of a successful ball launcher be used for making everyday life easier?

Engineering & science connections

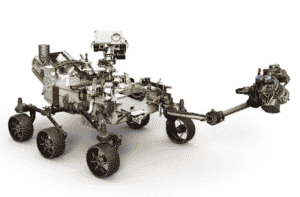

Perseverance Mars Rover. Photo by NASA/JPL-Caltech

Simple machines change the direction or strength of a force. People have been using simple machines throughout history, and we still need them today. An inclined plane or ramp, for example, lets you lift something that would normally be too heavy for you by spreading the work out over a longer distance. Moving trucks use inclined planes so that it’s easier to load heavy objects. If a box is too heavy to lift directly onto the truck, you can slide it up an inclined plane instead. Other simple machines: wheel and axle, pulley, screw, and wedge.

-

The ability of a simple machine to amplify force (a push or a pull) is called mechanical advantage. In the case of a lever, the mechanical advantage increases as the fulcrum is moved further from the center to one end of the beam. Thanks to mechanical advantage, people use levers to lift heavy objects they could not lift by themselves.

-

Mechanical engineers use levers as parts of their designs for new products. For example, most robots integrate levers to enable motion in the different joints. A robot needs to be able to do work with as little energy input as possible, and levers make that practical. Robots in auto manufacturing plants use levered arms to weld steel frames quickly and accurately. Doctors use levered robot arms to perform surgeries that are difficult to access by hand. The Perseverance Mars Rover uses a levered robotic arm to analyze mineral samples and drill for rock samples 45 million miles from Earth.

0 Comments