Overview

STEM careers

Time

Materials

Per Group:

- Candy

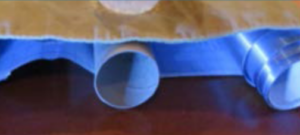

- Tubes of various sizes and materials (paper towel and toilet paper rolls, PVC pipe, bits of hose, soda bottles, cans)

- Rubber bands

- Ball bearings

- Balls

- Sheets of fabric

- String

- Gears

- Handles

- Paper cups

- Straws

- Paper towels

- Paper clips

- Tape

- Glue

- String

- Foil

- Plastic wrap

- Pens, pencils

- Paper

- Crayons

- Other everyday items useful for making a conveyor belt

Instructions

Teams design and create a conveyor belt that transports candy at least 4 feet, including around a 90 ̊ turn.

PREPARATION:

Decide if you want teams to have free access to all of the materials or if you want to distribute set amounts to each team. If the latter, decide if you want teams to be able to trade materials with each other.

ACTIVITY:

- Discuss students’ experience with different kinds of conveyor belts and describe the basic mechanics of conveyor belts.

- Explain the challenge and indicate the range of materials students can work with. Note that students can use their hands to make their conveyor belts move, but they can’t touch the candy (or the cups filled with candy) and the candy mustn’t fall off for their conveyor belts to be considered successful.

- Divide the class into small teams and tell teams to sketch some designs before choosing one. They should also write a list of the materials they will use.

- Ask each team to present their design. Encourage the listening teams to amend their sketches if they hear something that they think will improve their own design.

- Instruct teams to construct their conveyor belt.

- Test each belt and give teams the opportunity to redesign and rebuild a second version.

- Ask teams to present their conveyor belt to the class, and discuss the pros and cons of each.

Guiding questions

-

Which tubes make the best rollers for transporting candy?

-

From the available options, which material will help keep the candy stable on the rollers?

-

What if you had to make your conveyor belt go up or down a slope—how would you change the design?

Engineering & science connections

- In its most basic form, a conveyor belt is a frame with rollers installed at intervals along the length of the belt. The rollers are covered with something smooth or rubbery that helps materials to move without getting stuck. A conveyor belt can be motorized or manually powered, or it can move with the force of gravity.

- In 1913, Henry Ford installed conveyor belts in his car- building factories. He used assembly lines of workers to complete different tasks along the belts, making production more efficient than anyone thought possible. Although mass production began in the 19th century, Henry Ford and the conveyor belt made it the hallmark of 20th-century manufacturing.

- Engineers design conveyor belts in all kinds of industries to move things of all different shape and sizes. Some conveyor belts move small things like in these industries: pharmaceutical, food, bottling and canning, and packaging. Others move large items like in: the automotive industry, mining, shipping, agriculture, and aerospace. Conveyor belts even move people (and their luggage) at airports.

- Based on their use, engineers make conveyor belts of different lengths, strengths, and speeds:

- The longest conveyor belt system in the world—about 61 miles long—transports materials from a phosphate mine in the Western Sahara.

- The strongest conveyor belt runs in the mines of Chile; it can hold the equivalent of 24,700 people without breaking!

- While most conveyor belts move relatively slowly to keep the items in place, conveyor belts in one German mine move at 900 miles a minute.

Developed by IEEE as part of TryEngineering.org.

0 Comments