Overview

STEM careers

Time

Materials

Per Whole Group:

|

Per Team:

|

Relevant Terminology

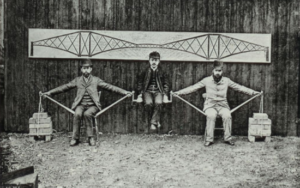

Engineers demonstrate the forces at play in a cantilever truss bridge, c. 1890. The sticks extending from the chairs are under compression; the men’s arms are under tension.

Compression: A force that squeezes an object from opposite directions, pushing two points towards each other. Smashing a can with your foot puts it under compression.

Span: To extend from one side of something to the other side, as a bridge does over a river.

Tension: A force produced from stretching or pulling something in opposite directions. A tug-of-war rope is under tension.

Truss: A structure made out of triangle shapes and designed to carry heavy loads.

Introduce

GETTING READY

Set up the tables or chairs 25 cm apart. This is long enough that a single straw (about 20 cm) will not span the gap. If you’re using longer straws, enlarge the gap to maintain the challenge.

INTRODUCTION

A truss bridge on the Boston & Maine Railroad in Northampton, MA. The bridge was built in 1887 for railcars, but today it is part of a hiking trail.

Bridges are a crucial part of our infrastructure. Not only do they help us get to our destinations, they allow us to cheaply and efficiently transport goods across long distances and many obstacles. Life would be very different without bridges.

Bridges and those that cross them are acted upon by several forces. Gravity is always working to pull a bridge down. The load on a bridge causes additional stress on the materials, resulting in parts of the bridge being squeezed together (compression) while others are pulled apart (tension). Suspension bridges are also susceptible to twisting (torsion) forces caused by wind.

Bridges come in a variety of designs, including suspension, cable-stayed, beam, arch, and truss. Truss bridges use a series of triangles for support and are commonly used for railroad bridges because of their incredible strength. You can demonstrate the strength provided by triangles by making a square out of tape and straws. Manipulating the square easily deforms the shape. But add a diagonal straw (or two) across the square and feel the difference.

Instructions

Ask participants to share what they know about bridges: how they work, how they’re built, and why they’re important. Correct any misconceptions and provide new information as needed.

Introduce the design challenge. Participants will work in small teams to build a truss bridge that spans at least 25 cm using only straws and tape. Once their bridge is complete, participants will place pennies or metal washers at the center of the bridge’s span to measure how much weight it can support.

- Distribute supplies to each team: 20 straws and tape.

- Give the teams time to plan and build their bridge.

- Test each design by placing the bridge between two chairs or tables.

- Place a paper cup on the bridge and add pennies or other weights.

- Observe how the bridge deforms (or collapses) under stress.

- Use a meter stick to measure how low the bridge hangs under stress.

- Redesign and retest bridges as necessary.

Evaluate the success of each design.

- Does the bridge span at least 25 cm?

- Did the bridge hold up to compression and tension forces created by the weight?

- How many pennies (or other weight) did the bridge hold before collapsing?

ACTIVITY VARIATIONS

Demonstrate compression by having two volunteers stand facing each other with their arms outstretched and palms touching. Have them lean in as they back their feet away from the center, forming a human arch. Demonstrate tension by having two volunteers lock hands, then lean backward while standing toe-to-toe.

Increase the challenge by spanning a longer distance or adding a requirement to support a certain amount of weight.

TROUBLESHOOTING

If a bridge does not naturally hold a paper cup, create a deck with some thin, light cardboard or material from a cereal box.

Guiding questions

GUIDANCE FOR YOUNGER CHILDREN

QUESTIONS TO ASK AFTER THE ACTIVITY

- How many pennies or how much weight was your bridge able to withstand before breaking? Was this more or less than you expected?

- What are two things that you, as well as engineers, consider when designing bridges?

- If you had more time to make another bridge or change your design, would you do anything differently? Why?

- Can you think of any other structures that use trusses or triangles for support?

- What was the most challenging part of this activity?

GUIDANCE FOR OLDER YOUTH AND ADULTS

QUESTIONS TO ASK AFTER THE ACTIVITY

- What type of bridge did you model your bridge after, and why?

- What modifications did you make to your design, and why? What design solutions did you use to combat the forces acting on the bridge?

- Did your bridge buckle or snap? Did the failure occur all at once or did it bend and deform before breaking?

- Which parts of your bridge are under compression versus those under tension?

Engineering & science connections

GUIDANCE FOR YOUNGER CHILDREN

Engineering Connections

A bridge is a structure that allows people or vehicles to cross over an obstacle such as a gorge, valley, road, railroad track, or body of water, rather than going around it or through it. There are many different types of bridges, including suspension bridges, cable-stayed bridges, arch bridges, and truss bridges. In determining what type of bridge to build, engineers must consider how heavy a load the bridge must support and how far it must span.

The load is the weight and all of the forces that a bridge must be able to support. There are two types of loads that engineers consider when designing bridges: the dead load and the live load. The dead load is the weight of the bridge itself. Bridges are usually built from concrete and steel and are, therefore, very heavy. They have to hold themselves up before they can hold all of the people and vehicles that will use them! The live load is the weight of all of the other things— people, cars, bicycles, snow, and wind—that will also be added to the bridge. Bridges have A LOT of weight to hold up!

Science Connections

For a bridge to remain standing, it must be able to apply a force that is equal to everything on it, but that acts in the opposite direction. Imagine you and your friend are pushing against each other with the exact same amount of force. Neither of you move, right? Well, the same is true with bridges. If equal forces act in opposite directions, the bridge won’t move and everything will work just as it should. However, if the forces acting on the bridge are greater than what the bridge applies in return, the structure can no longer support the bridge and it could break. This can happen when the load on a bridge is too large or for other environmental reasons. In 1940, the Tacoma Narrows suspension bridge in Washington State collapsed. The wind blowing past it caused it to bounce up and down more and more until finally the cables couldn’t hold the bridge up anymore.

GUIDANCE FOR OLDER YOUTH AND ADULTS

Engineering Connections

The type of bridge that an engineer designs to span a particular obstacle depends on the overall length between the bridge supports and on the loads that the bridge must withstand. Suspension bridges support the roadway or deck using vertical cables that are connected to even larger supporting cables that are draped between two tall towers. These towers are responsible for supporting the majority of the deck’s weight, through tension in the vertical and horizontal cables. These forces are carried by the towers to the giant concrete bases on which the bridge sits and, ultimately, to the earth. Because the cables can carry high tension forces, longer main spans are achievable than with any other type of bridge. Examples of suspension bridges include the Roberto Clemente Bridge in Pittsburgh and the Golden Gate Bridge in San Francisco. The Akashi Kaikyo bridge in Japan spans over 11⁄4 miles between the two main towers. By always working to increase the distance a bridge can span, engineers can pass over large waterways and still allow for huge ships to pass underneath without fear of hitting the bridge.

Science Connections

The ability of one bridge to span a greater distance than another bridge or to support a greater load is a result of that bridge’s ability to deal with forces of tension and compression. Tension is a force that is created when two forces are pulling on an object in opposite directions, like the rope in tug-of-war. Compression is the opposite of tension and occurs when two forces are pushing the ends of an object toward each other, like when you crush a can by stomping on it. Forces of compression and tension act on every bridge, so it is important that the bridge is designed to withstand these forces.

Engineers always consider the ability of certain building materials to resist compression and tension when constructing bridges. For example, concrete is incredibly strong under compression, which makes it a good choice for the concrete bases on which the towers sit. But you will never see concrete used in the parts of a bridge that will be pulled on. For these, steel is a far better choice because of its strength under tension.

Activity created by the Museum of Science and Industry, Chicago. All rights reserved. http://www.msichicago.org/online-science/activities/activity-detail/activities/straw-bridges-1/

Supplemental content adapted for Dream Big Activities by the Carnegie Science Center.

0 Comments