Overview

Materials

Per Team of 3-4 Students:

- 20 1 1⁄2″ roofing nails (oversize head can be pushed into foam with thumbs and length won’t protrude out the backside)

- 2 beam supports, approximately 4″ tall (books, bricks, etc.)

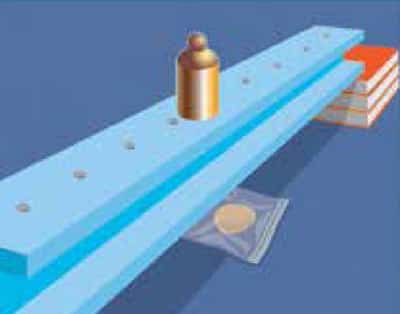

- Weight of 1–2 pounds (same weight for each team)

- Tape measure

- 4′ x 8′ sheet of 3/4″ thick foam house insulation (can supply 3 teams, if cut carefully)

- 2 eggs, each in its own zip-locked bag

Instructions

Students construct foam beams under specific constraints, so that the beam can support weight without touching an egg beneath it.

PREPARATION:

For each team, cut the foam house insulation into the following strip widths.

- 4 pieces, 2″ wide, 48″ long

- 4 pieces, 3 1⁄2″ wide, 48″ long

- 2 pieces, 5″ wide, 48″ long

ACTIVITY:

- Give teams the following challenge: Build a 48″ long beam under the following constraints:

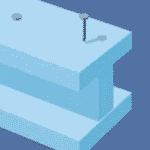

- Connect some or all of the foam strips provided using no more than 20 1 1⁄2″ roofing nails.

- You can’t alter the size of any of the foam strips.

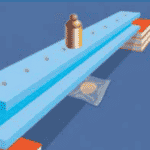

- The beam rests only on the end supports, 4″ above the ground.

- The bearing length at each end of the beam should be 2″ long so that the clear span—the inner distance between supports—is 44″.

- No part of the beam can be touched by team members while weight is being placed on it.

- An uncracked fresh egg is placed beneath the beam midspan.

- The test load is placed on the beam, above the egg. Note whether the beam touches or cracks the egg.

- Give teams 20 minutes to build and self-test their beam using their egg.

- As a class, test each beam and record the results to see which beams succeed at bearing weight without touching or cracking the egg.

Guiding questions

-

Which arrangement of foam strips provides strength without too much weight?

-

How far apart can you put the nails and still create a beam that will support weight?

-

What would it take to make an even longer beam, using these materials?

Engineering & science connections

- Deflection is the distance an object or structure bends or twists from its original position. Deflection can be caused by many sources including: weight, temperature, and errors in construction or design. Engineers endeavor to make sure a structure is safe and useable for its purpose. So while some deflection in a structure might be safe, it could still make the structure unusable.

- Architects and engineers must be very aware of the materials that they use when designing structures for specific purposes. For example, roof beams will have different deflection limits than floor beams, and steel frames that will support glass panels must be designed to prevent glass breakage caused by deflection.

- Truck and car frames, machine frames, and other systems contain beam structures that are designed and tested for acceptable limits of deflection in a similar way as beams used in buildings. Engineers control deflection through their choice of materials, structural shapes and orientations, and operational temperature limits.

This hands-on civil engineering activity was developed for the Emagine K-12 Outreach program within the College of Engineering and Science at Clemson University.

0 Comments