Overview

Materials

Per Class:

|

Per Team:

|

Instructions

PREPARATION:

- Cover the ping-pong ball with Velcro or similar material and construct the target.

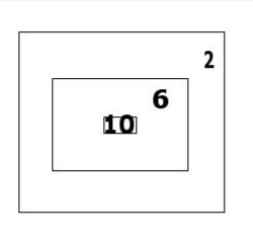

- Mark the target to indicate different numbers of points, depending on where the ball lands: the bull’s-eye is 10 points, the middle is 6 points, and the outer area is 2 points.

Make sure that the ping-pong ball will stick to the target when it is volleyed and that the target is positioned properly to enable students to potentially hit the bull’s-eye. (Consider the age of your students to determine what distance from the target your students must stand when hitting the ball.)

Make sure that the ping-pong ball will stick to the target when it is volleyed and that the target is positioned properly to enable students to potentially hit the bull’s-eye. (Consider the age of your students to determine what distance from the target your students must stand when hitting the ball.)

ACTIVITY:

- Ask if any students have ever played tennis and if so, to describe the construction of the racket and the materials it is made of. If you have a racket on hand, pass it around for students to inspect. Note that engineers have been improving on the materials and construction of tennis rackets for centuries. Tell them that rackets were first made out of wood, then steel, then graphite. As a class, use these historical changes in materials to help brainstorm a list of the qualities students think the engineers are trying to improve (lightness, strength, durability).

- Divide students into teams of 3 or 4 and introduce the design challenge. Indicate the materials teams can use to meet the challenge.

-

Tell teams to sketch 3–4 designs, keeping the materials available in mind. They can create these designs individually, in pairs, or as a whole team. They then should discuss the designs as a team and determine which one is best. Once they pick the best design, tell them to list which materials they will use.

Tell teams to sketch 3–4 designs, keeping the materials available in mind. They can create these designs individually, in pairs, or as a whole team. They then should discuss the designs as a team and determine which one is best. Once they pick the best design, tell them to list which materials they will use. - Direct students to construct their racket, improving on their original design as needed. Groups should make note of changes they make to the original design based on challenges or inspiration they find during construction.

- Test each racket by having team members hit the ping- pong ball to adhere to the target. Explain the following rules:

- Each team member tries to hit the bull’s-eye up to 3 times.

- The 6 highest scores determine each team’s score.

- Talk about why some rackets did better than others and how materials and construction could be improved to make the racket more durable.

Guiding questions

-

Why does a tennis racket have mesh instead of a solid surface? How does this help hit the ball further?

-

How fine or loosely spaced should the weave of the mesh part of the racket be?

-

How can the mesh part be attached to the racket frame so that it doesn’t pull out when you hit the ping-pong ball?

-

How big of a surface area do you need for your racket?

-

What’s the best thickness for the handle to make it easy and natural to grip?

Engineering & science connections

- To ensure fair play, there are certain constraints engineers have to abide by for designing professional tennis rackets: The frame cannot be longer than 29″ (15.5″ for the hitting surface), nor wider than 12.5″ (11.5″ for the hitting surface). The hitting surface must be made of evenly spaced crossed strings, and there can be no objects attached. Because of these restrictions, engineers rely primarily on changes in the materials they use to improve the functioning of the tennis racket.

- In the 19th century, rackets were made of wood and the strings were made of animal gut. In 1947, rackets started being laminated—or constructed in fused layers—to make the wood stronger. The first steel racket was created in 1968, and rackets became larger as well to make them more powerful. Starting in the 1980s, rackets have been made of graphite, and the search for ever lighter, stronger materials is ongoing. Gut has been replaced with a range of materials, such as nylon, polyamide, and other polymers to both increase tension and to decrease the cost.

- The crossed strings of tennis rackets create an elastic surface that moves slightly with the ball and then bounces back more quickly than a solid surface could, giving the ball extra power on its return. Players are actually able to change the elasticity or tension on their rackets (within a range): higher tension (or less elastic strings) allows the player more control while lower tension (or more elastic strings) gives the player more power. Simple changes to the design of a racket can cause dramatic changes in a player’s performance. For example, in the mid-1990s, Michael Chang was one of the shortest professional tennis players. To compensate for his height (and arm length) difference, he asked tennis racket company Prince to create a 28″ racket for him (at the time most rackets were 27″ long). Few people even noticed the change to the racket, but Chang’s serve improved dramatically: he served 256 aces in 1993 with a 27″ racket, and 366 in 1994 with a 28″ racket.

Activity courtesy of TryEngineering.org

0 Comments