Overview

STEM careers

Topic

Time

Materials

Per Class:

|

Per Team of 2-3 Students:

|

Instructions

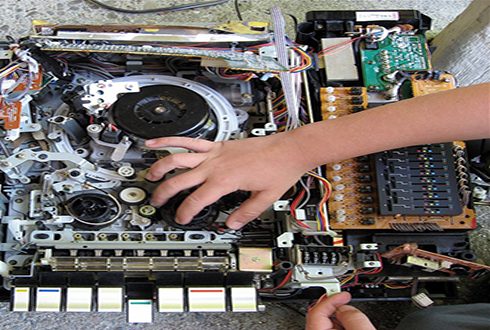

- In this activity, students deconstruct a device, getting an opportunity to see its inner workings and consider the engineering work and scientific principles behind it. So begin by deciding on a device students will work with. Everyone should work on the same type of device, or half the class on one type and half on another. Guidelines for choosing the device:Device can be taken apart with simple tools (screwdriver, snap fits) and does not require detailed disassembly instructions.

- Size: two or three students can work around and on it.

- It has between 4 and 30 mechanical components (e.g., springs, gears, bearings) inside, plus an electrical aspect, if possible.

- It costs less than $10 per device (in addition to hardware, toy, and big-box stores, check second- hand stores or the salvage yard).

- Suggestions: wind-up toy, ballpoint pen, mechanical pencil, stapler, disposable camera, flashlight, electrical outlet or switch, clock, timer, fishing reel, smoke detector, telephone.

- Become an expert on the device: take it apart and put it back together enough times so that you and any assistants can effectively troubleshoot.

- Create any instructions that seem necessary, based on how difficult you found the disassembly/ reassembly.

- Divide students into teams of two or three.

- Distribute a device and disassembly kit to each team.

- Give teams about 5 minutes to investigate their device (e.g., push buttons, turn it on), and guide them to think about what the device does, what parts are inside, and how it works.

- Give students time to take apart the device; suggest taking notes that will help them put it back together and answer questions about how it works. Once it is disassembled, tell students to put it back together again.

- Instruct teams to use notes and sketches to answer questions about the device: how it works, what parts it has, what other machines use similar parts, how it was assembled, and what types of engineers may have been involved in creating it.

- Have one member of each team present the team’s answers and sketches; record the answers on the board or butcher paper. When talking about types of engineers involved, keep adding students’ ideas to the list so that it reflects the breadth of the engineering profession (materials engineers, industrial engineers, environmental engineers, etc.)

PREPARATION:

ACTIVITY:

Guiding questions

-

What does the device do and how does it work?

-

How many parts are inside?

-

What sciences and what scientific principles apply to this machine (e.g. chemistry in batteries and materials, physics in electromagnetism and load transfer, biology in human factors)?

-

What other machines would you expect to find similar components in?

Engineering & science connections

- Reverse engineering is the process of taking apart an object to see how it works in order to duplicate or enhance the object. Engineers often do this to get ideas about how to duplicate or improve products, on everything from cars to cellphones to software programs.

- The ease with which a device can be assembled or repaired is important to engineers; if it’s too complicated or expensive, it’s not practical. If the students had an item with three times as many parts but performed the same function, it would have been much more difficult to determine how it worked and more difficult to repair.

- Engineering is a team effort—more than one type of engineer may be involved in making a device. In this experiment the group members worked together to determine how their object worked. It probably helped that each student brought a different knowledge set, similar to different types of engineers.

The Synthesis Engineering Education Coalition, Funded by the National Science Foundation. Member universities include Cal Poly-San Luis Obispo, Cornell, Hampton, Iowa State, Southern, Stanford, Tuskegee, and the University of California at Berkeley.

0 Comments