Overview

Materials

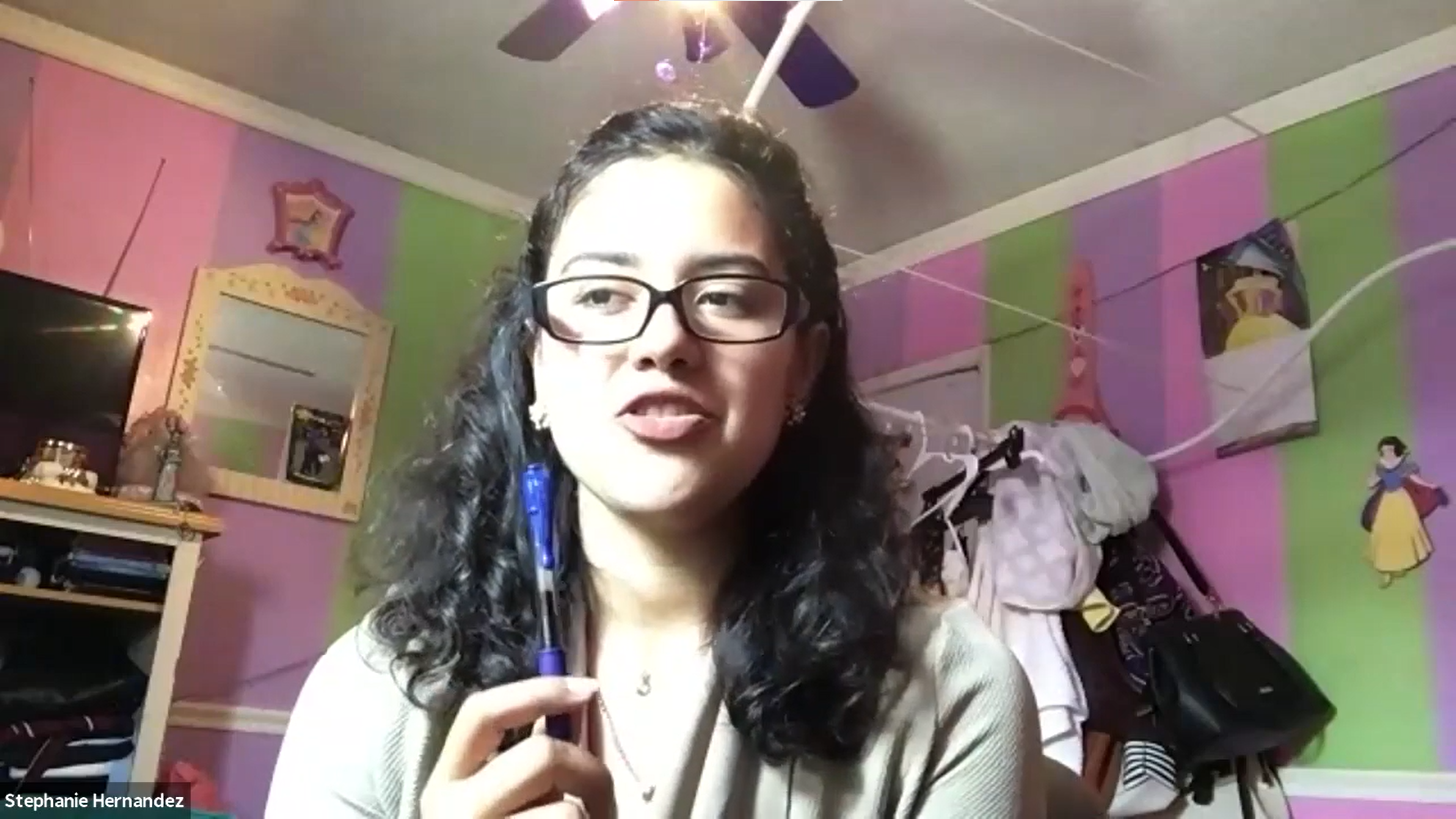

- At least 3 “click” pens that have 5 or 6 parts each. Make sure they’re the kind that click on and off and that they come apart. Some pens are just one big piece. For this activity, the more pieces a pen has the better. (See photos of click pens in video above).

- Ideally you should have pens that are the same style for consistency, but if you don’t, it’s OK to use different ones.

- A timer. Either a stopwatch or smartphone timing app.

- Writing materials and paper for collecting data

- After completing steps 1-2, you will need at least one partner to help you test your design in steps 3-5 (Grab a sibling, friend or a parent/guardian!)

Instructions

- Identify the Problem

- The most critical step of any engineering challenge is to understand the problem you are trying to solve.

- Examine your pen. How do you think a pen like this is put together in a factory? What steps must happen for it to be built perfectly each time?

- Did you know that many products with different parts are put together in an assembly line? And they are operated by a person or robot stationed at each step in the process of putting something together.

- Why do you think assembly lines might make the work of putting together a large number of pens easier or faster than each person or robot assembling all the parts of a pen themselves?

- The problem you are trying to solve is to design your own assembly line in order to put together a collection of click pens as quickly as possible. Here are the specs:

- You will design the assembly line for you and your partner(s). Your partner(s) will follow your instructions to test the assembly line.

- You must determine how many pens you will assemble (minimum of three).

- Each pen has to be assembled completely and accurately in order to be counted.

- Each assembled pen must click and write correctly in order to be counted.

- The most critical step of any engineering challenge is to understand the problem you are trying to solve.

- Brainstorm Designs

- Take a pen apart and put it back together to explore how the pen is assembled. Write down the steps you took to assemble the pen and to make sure that it works properly.

- Design an assembly line for at least two people (or more if you have additional family members or friends who can participate). Determine which assembly roles each person will take on.

- Figure out what order you think is best for putting together the parts of each pen, which person will work at each assembly station, and what actions will happen at each station.

- Disassemble all of the pens you have, sorting the pieces into piles for an assembly line.

- If your pens are different, consider if you need to make adjustments to the steps in your assembly line.

- Test It

- Invite your partner(s) to help you test your assembly line. You will test your design at least twice. This will help you see if you can improve your design later.

- Explain the instructions for your assembly line and review the specific tasks along the line.

- Remind your partner(s) that they will need to help you put together all the pens as quickly as possible.

- Get ready to time your assembly line with a stopwatch or smart phone.

- For Test 1, you will gather baseline data on how well your first assembly line works.

- Start your first run! After all your pens are assembled, record your baseline time.

- Check that each pen clicks and writes properly with no missing parts.

- Discuss the results, noting any problems you had.

- Evaluate and redesign

- What could be improved so that your process of assembling pens is more efficient? Discuss with your partner any changes you would like to make using these questions:

- At what step(s) did the pen parts pile up? In other words, were there any bottlenecks?

- Was anyone reaching for parts awkwardly? Could positions be changed to make movement easy?

- Were any of the pens not clicking or writing properly—a quality issue? At what point in the process did the problem occur?

- Would it help to assemble certain parts before the main assembly? This is known as subassembly. If so, which parts?

- What could be improved so that your process of assembling pens is more efficient? Discuss with your partner any changes you would like to make using these questions:

- Make Changes and Try Again!

- Disassemble all of the pens and set up for your redesigned assembly line.

- Test 2: Do another assembly line run! Record your results. Were you able to beat your time? Feel free to test a third time if you and your partner(s) are game!

- Share Your Results with a teacher, parent/guardian, or DiscoverE!

- You can email photos to DiscoverE at social@DiscoverE.org or post on Instagram/Twitter using the hashtag #DiscoverEChallenge

Pen Factory! is adapted from an activity created by Northrop Grumman industrial engineers for use in their student outreach efforts.

0 Comments